A Historic Moment for Bray Plastics…..

Bray Plastics: Now 100% Employee-Owned! We're thrilled to announce a historic moment for Bray Plastics! As of Wednesday 12th June, we are officially a 100% employee-owned company, operated through an Employee Ownership Trust (EOT). This is a significant change that…

What is Laser Cutting?

What is Laser Cutting? Laser cutting is a technology that uses a thin, focused laser beam to vaporise, burn or melt materials, resulting in a cut edge or etched surface, depending on your requirements. It is typically used for industrial…

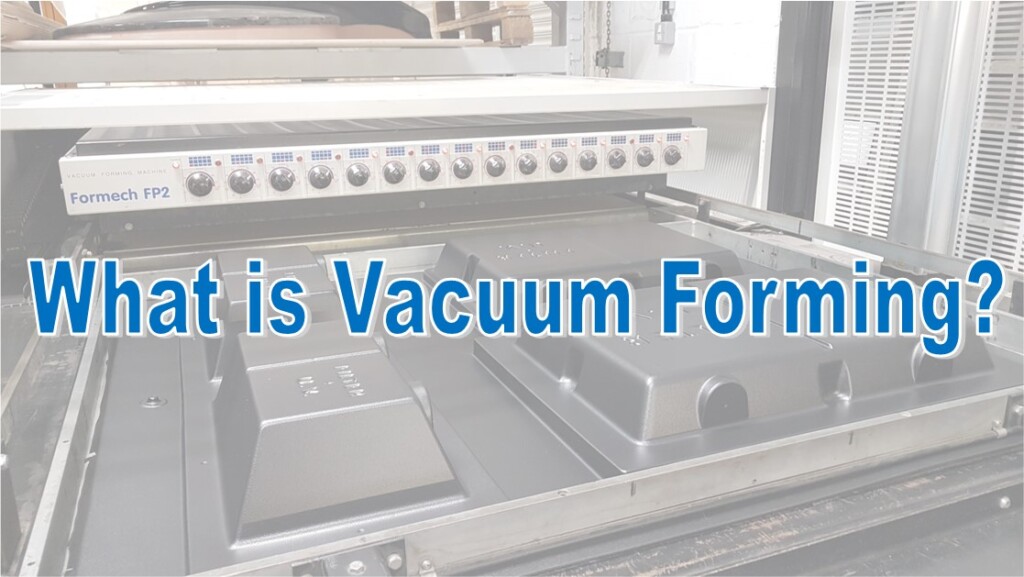

What is Vacuum Forming?

What is Vacuum Forming? Vacuum forming is a manufacturing process that uses heat and vacuum to shape plastic sheets into three-dimensional objects. It is a relatively inexpensive process that can be used to produce high-quality parts in a short…

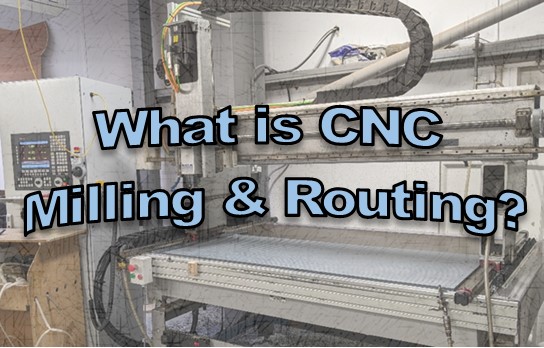

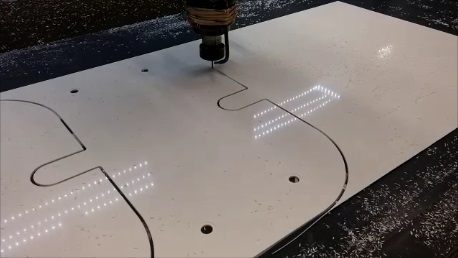

What is CNC Milling & Routing?

What is CNC Milling & Routing? CNC milling and routing are two closely related manufacturing processes that use computer numerical control (CNC) to create precise parts and components from a variety of materials. Here at Bray Plastics we predominantly…

Custom Enclosures & Covers

Are you stuggling to find the right off-the-shelf enclosure? Do you have a specific design in mind? Our custom enclosure service can help! We will work with you to produce the perfect enclosure or cover for your…

Latest Equipment for Routing & 3D Printing

Here at Bray, we rely on our machinery and equipment to provide the best service to our customers. Sadly, this machinery & equipment gets old and sometimes either needs upgrading or replacing. The old Anilam CNC control on one of…

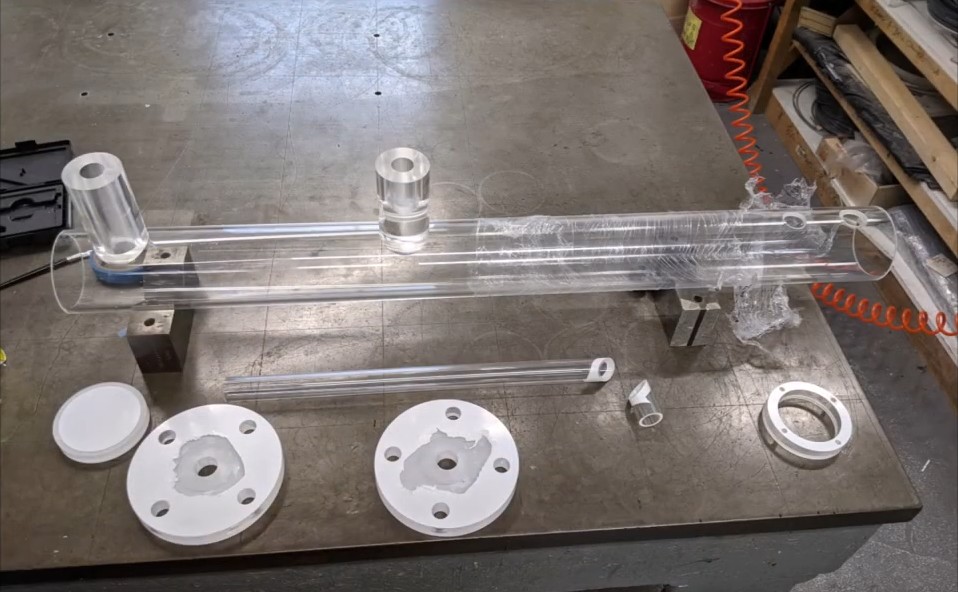

Machining Acrylic & PVC Tubes

Bray Plastics are suppliers of machined and fabricated plastic components to industry. Our customers are diverse and regularly present Bray with manufacturing challenges that helps to seal our future commercial partnership. Bray have manufactured housings for anti-drone protection systems, heart…

At The Cutting Edge

You already know that Bray Plastics are experts in plastic machining and design solutions, but did you also know that we complete many laser-cutting projects? Marking or cutting some non metallic materials can be quite problematic. The substrate surface may…

Machining for the Medical & Scientific Industries

Bray Plastics has an enviable and varied range of repeat customers in a diverse range of industries. With a history of machining and fabricating with acrylic materials, Bray’s engineering expertise is used by research institutes and scientific laboratories for specialist applications, such as:- X-ray…

Machining for the Military

Did you know that due to our experience and expertise in plastic and metal engineering, Bray Plastics are a sought after designer and manufacturer in the Defence industry? We have completed a wide range of projects for Military suppliers –…

Plastic Storage Units for Hospitals

Bray Plastics has an enviable and varied range of repeat customers in a diverse range of industries. One recent example is Performance Storage Systems Ltd for whom we have previously carried out projects for hospitals. They required workstation equipment being…

Not All Acrylics Are Equal!

The most common name used to describe clear plastic would appear to be Perspex, and there are many others, but they are all actually trade names for Acrylic or PMMA (Polymethylmethacrylate). Acrylic is used in a huge range of products…

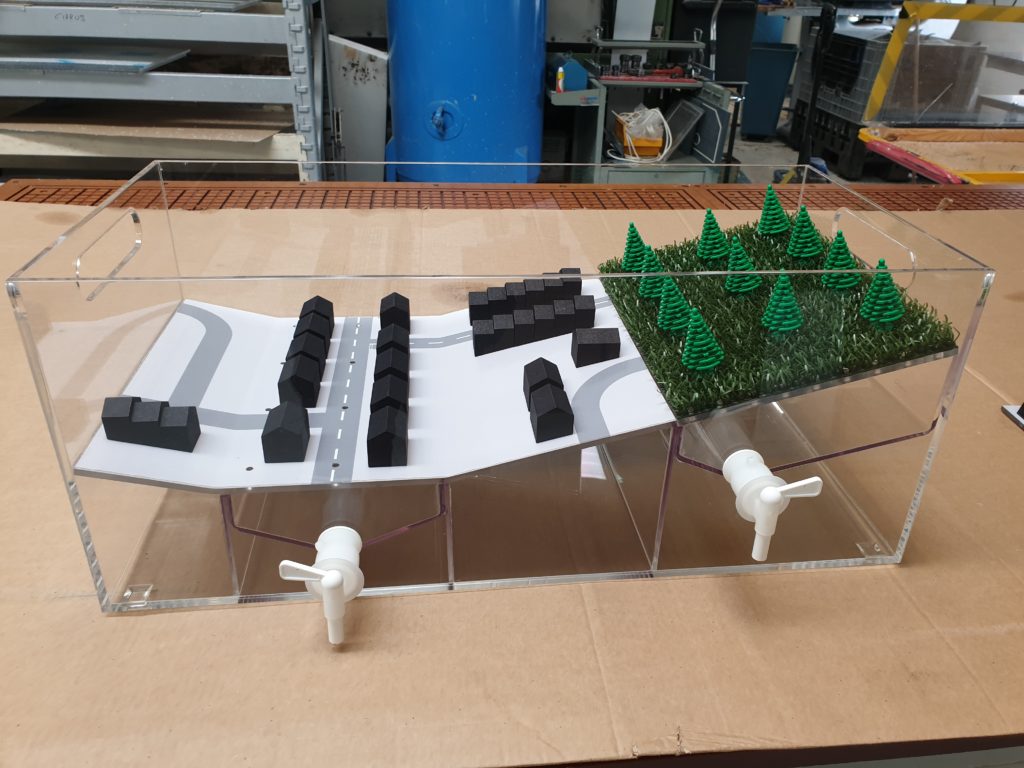

The Benefit of Working Demonstration Models

Demonstration and working models can communicate ideas and concepts far quicker than verbal explanation or the written word. However, finding a model maker/fabricator who can turn your concept into reality can be an uphill struggle, and that is where Bray…

Machining PE for Military Vehicles

EKA are one of the World’s premier designers and producers of recovery vehicles for the military. Bray Plastics are pleased to be one of their suppliers, manufacturing a range of products in Nyloil, acetals, and UHMWPE. The video shows Ram…

Producing Covid-19 visor components

In an environment where the level of uncertainty permeates through the whole of our society, it is gratifying to know that we at Bray Plastics are still able to help and contribute in a meaningful way to that society. The…

Coronavirus – Covid 19 Update

We would like to reassure our customers that at present Bray Plastics does not have any employees impacted by the current Coronavirus (Covid 19) pandemic and for now it is business as usual. This may change in the coming days…

Reduced Production Costs for World Leading Product

When designers and manufacturers have invested their time and expertise heavily into producing a world leading product, they want to ensure it looks as good as it performs. Specialised Imaging Ltd are industry leaders in the design and manufacture of…

A Simple Solution to a Potentially Expensive Problem

Welcome to another update and example of the diverse markets and applications Bray Plastics have for their plastic fabrication and engineering skills. Airtask are a company who provide bespoke mission-based aviation solutions to Government and commercial customers. They own and…

Bespoke Fabrication of Enclosures

From a mobile distribution box for children’s books to custom electronics enclosures for a major brand sponsoring motor sports, Bray Plastics has experience in designing, fabricating and manufacturing enclosures from a variety of plastics, such as acrylic, polypropylene, ABS, PVC…

Improving & Customising Off-The-Shelf Components

The extensive range and availability of off the shelf components and assemblies in manufacturing, greatly assist design engineers across a wide range of industries. However, there can be occasions when these assemblies will require modification to be more suitable for…

So You’ve Got A Plastics Fabrication Project? What Now?

Well firstly, congratulations, you’ve reached a big milestone when you’ve pushed an idea to the prototype or production stage. But now you might have reached a phase where you need some more expertise on how you are going to complete…

Sindanyo H91 – the alternative to Duratec®

Now that Duratec® 750 and Duratec® 1000 have been discontinued, what is the alternative when you require a quality, thermal and electrical insulating product? TENMAT have developed a High Temperature Cement Board which is suitable for tough applications where thermal…

Jigs & Fixtures – The Secret Of Successful Manufacturing

One of the unsung heroes of successful manufacturing is used intensely by the ‘big names’ but has a much lower profile with the sub 50 employee manufacturers. “What is this gem?” I hear you cry, “Jigs and fixtures” came the…

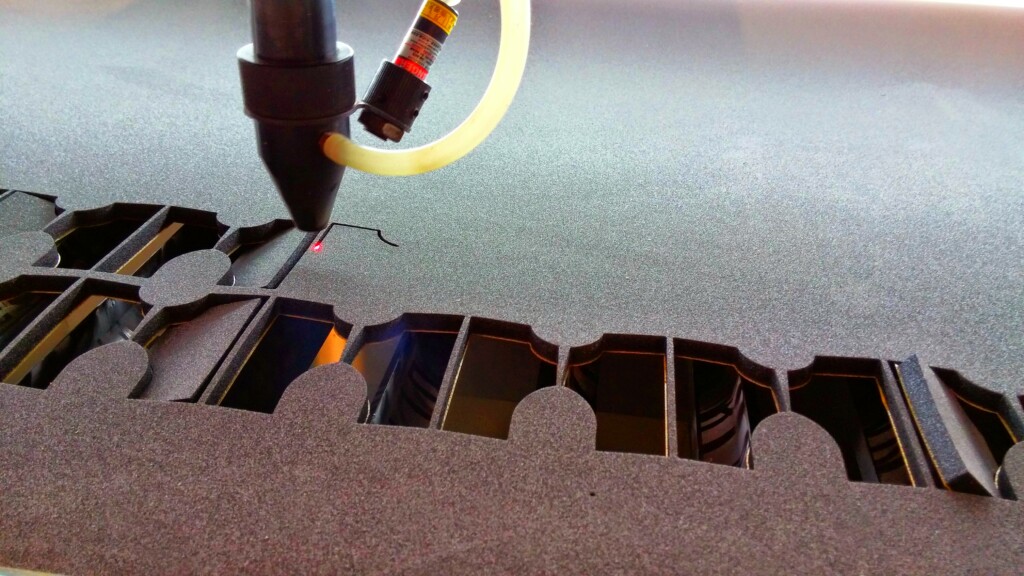

Versatile Laser Cutting

It can be difficult to cut or engrave softer materials and substrates accurately. Particularly when they may contain adhesive or have an inconsistent density. Bray Plastics use their laser as a CNC ‘scalpel’ to accurately cut a range of diverse…

Bespoke Machining for Strobe Housing

Bray Plastics were delighted to be approached by WheelRight Ltd for assistance in machining and fabricating a new enclosure used for heavy goods tyre condition monitoring. The 450mm x 250mm enclosure was machined from 40mm nylon 66 and had various…

Repulse® – Polycarbonate housing solution

Drones, UAVs or unmanned aerial vehicles are a new industry that have both hobbyist and industrial applications. Used in the right hands they can inspect, survey, observe and deliver at low cost and can bring great advantage to the user.…

Merry Christmas from all at Bray Plastics

We would like to wish everyone a very Merry Christmas and a Happy New Year. We are here until 10.30am on Friday 21st December 2018 and will reopen on Wednesday 2nd January 2019. We hope you have a good…

Showcase Your Components or Equipment Effectively

How can you show your components or equipment in their best light? Functional clear acrylic displays are an effective way to demonstrate equipment and components. They can be used for exhibitions, in house demonstration, research and training. The modern, eyecatching…

Take The Hassle Out Of Sourcing Enclosures

Sourcing suitable electronic and electrical enclosures, particularly in low volume can be a tedious task. Add to that a customising requirement by modifying those enclosures to suit specific applications then an already onerous task has also become a daunting one.…

Plastic Fabrication For Your Industry

EPS (Expanded Polystyrene) and EPP (Expanded Polypropylene) have high insulation values and are used extensively in the packaging, refrigeration and building industries. These materials are mostly moulded for application and production but can also be machined for prototyping and proof…

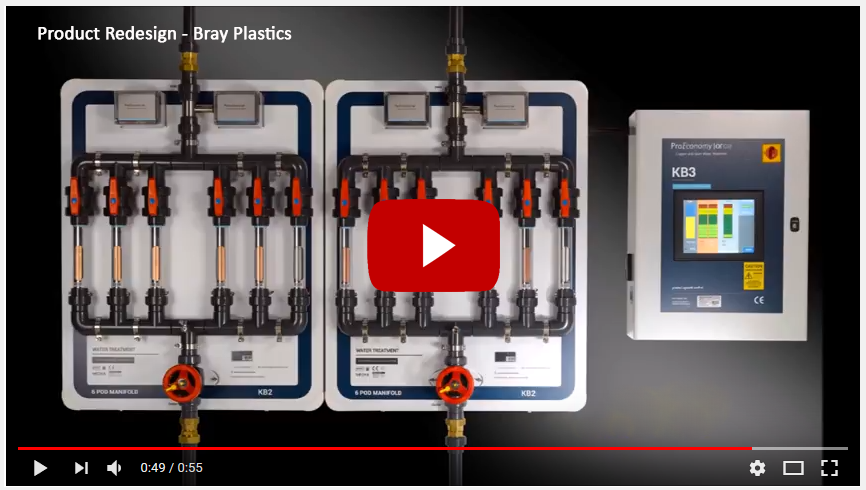

Product redesign for commercial success

Reviewing and/or re-designing your own product is a difficult task, particularly if you have been closely associated with it. This was the dilemma ProEconomy faced with their ‘Orca’ water treatment station for Legionella control. Orca was a successful and proven…

Materials Used in Vacuum Forming

Materials used in vacuum forming are usually thermoplastics. Almost all thermoplastics can be supplied in sheets and so can be vacuum formed. It’s also suitable for transparent materials such as acrylic, making it ideal in the aeronautical industry creating cabin…

What is Vacuum Forming?

Vacuum forming is a type of thermoforming, where a plastic sheet is heated until it becomes mouldable, when it is then stretched over a mould and the force of the vacuum pulls the plastic against the mould. Vacuum forming can…

The difference between vacuum forming & thermoforming.

The terms vacuum forming and thermoforming are usually interchangeable, however thermoforming is a more generic term and refers to a range of fabrication processing where a plastic sheet has been heated to its ‘plastic’ malleable state and then shaped using…

What is Thermoforming?

Thermoforming is a term used in plastic engineering to cover a variety of processes. All thermoforming involves heating a plastic sheet to its pliable plastic state. Different plastics require a different temperature and length of heating to reach their malleable…

Merry Christmas from all at Bray Plastics

We would like to wish everyone a very Merry Christmas and a Happy New Year. We are here until midday on the Thursday 21st December 2017 and will reopen on Tuesday 2nd January 2018. We hope you have a…

How to interface with bespoke fittings

Most injection moulded PVC fittings interface well with other PVC fittings. A problem arises when these fittings are expected to interface with custom or bespoke components. Bray Plastics design and machining facilities help us to find solutions for our customers…

Sourcing machined components in small quantities.

Specialist equipment manufacturers can find it difficult to source machined components, particularly in small quantities. Finding the right supplier able to provide the skill set along with the willingness to help is critical. Shearwater, a manufacturer of counter surveillance instruments…

From Concept to Profitable Product

Helping designers turn their ideas into profitable product is one of Bray Plastics’ primary functions. The example shown is a sensor housing first fabricated for proof of concept and testing. It also allowed for a pre-production run. On approval, we…

Plastic and Metal Machining – See the Results!

In the last few years, Bray have been used by its customers for general plastic machining and fabrication. Our customers’ confidence in Bray as a supplier, has led them to use us to source other components and services in non-plastic…

Acrylic Machining for the Medical Industry

Clear Acrylic (Poly(methyl methacrylate) is used extensively in the medical industry. Acrylic vacuum chambers, cabinets, boxes, doors and windows can be found in hospitals and laboratories around the world. Premac lead loaded acrylic is used for radiation shielding of radio…

Plastic machining for cost-effective prototypes

Peli BioThermal is a world leader in thermal packaging, they use innovative design to enhance their products for their customers, prototyping large components in polypropylene and polystyrene foams. These can be used and tested to obtain ‘real world’ data before committing to tooling and production methods. Bray Plastics have been pleased to help Peli BioThermal by machining these foams. Intricate shapes and forms have been achieved on time and budget enabling both proof of concept, fit and application.

Bespoke enclosures for electronic instruments

When electronic instrument designers have completed, tested and proved hardware and software, housing their hard work can be a bit more tricky, particularly when prototyping or producing low production runs. Bray Plastics have an answer to this dilemma by fabricating…

Customising Enclosures To Meet Your Requirements

As an electronic enclosure distributor Box Clever Components can supply a range of enclosures from the industry leaders including Hammond, OKW, Fibox, Multibox, BCL, Spelsberg, Bopla, SLM etc. The one thing that links all these manufacturers is the likelihood that…

Manufacture of Specialist Equipment

Specialist equipment manufacturers and designers can sometimes find it difficult to source bespoke and custom parts. Their expertise invariably lies in understanding the application problem that their product must fulfil. Identifying and sourcing individual components whether mechanical, electrical, or electronic…

Manufacture of Coolant Pack Prototypes

A world leading manufacturer of temperature controlled packaging has used Bray Plastics to produce prototype housings for coolant packs. These prototype packs, which will ultimately be blow moulded from HDPE (High-density polyethylene), were produced by rotocasting polyurethane resin. Working from…

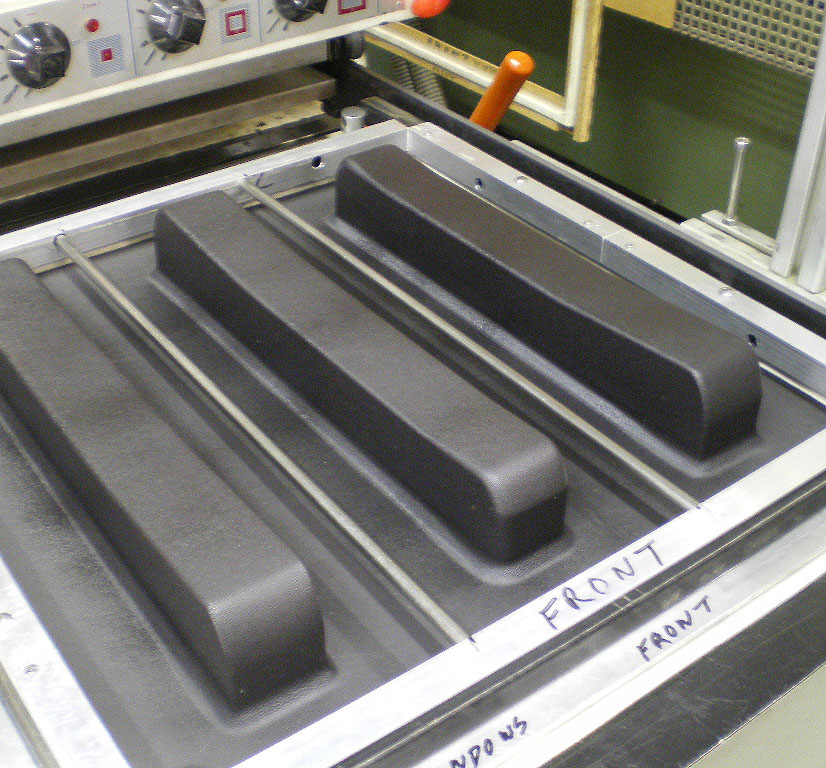

Reproduction of Components for Prestige Car Manufacturer

A prestige car manufacturer needed to supply obsolete Bakelite (or polyoxybenzylmethylenglycolanhydride – an early plastic) components to support the vintage fleet of vehicles around the world. Bakelite has its own unique colour, texture and mechanical properties but is no longer…

Extreme Laser Cutting!

It can be difficult to cut or engrave softer materials and substrates accurately. Particularly when they may contain adhesive or have an inconsistent density. Bray Plastics use their laser as a CNC ‘scalpel’ to accurately cut a range of diverse…

3D Printing and Prototyping

The recent installation of 3D printing machines at Bray Plastics further enhances the range of plastic fabrication and prototyping services we can offer. We use your .stl files to print your component. By adding traditional skills of machining, forming and…

Roto Casting

3D printing and prototyping along with Roto Casting are just some of the services Bray Plastics can offer its customers. The images illustrate tooling and a prototype of a blow moulded cassette used in the refrigerated packaging industry. Files supplied…

Nylatron Chain Guides and Wear Blocks

Nylatron chain guides and wear blocks, as illustrated in the video below, are just one of a myriad of components and products that Bray Plastics manufacture for their customers. Evoke Supplies of Oxford regularly ask Bray Plastics to produce one-offs…

Suppliers for Medical Equipment Manufacturers

Bray Plastics have established a primary position as suppliers to Medical equipment manufacturers. This video gives a brief glimps of the process to manufacture Glove port assemblies in chemical and biological isolators used extensively by the NHS and research establishments.…

New 3D Printing Facilities!

Bray Plastics are delighted to offer the addition of 3D printing services for its customers. We have sourced two printers – a Formlab 2 SLA unit for fine detail and a 3DP FDM (Fused Deposition Modelling) unit with a massive…

CNC machining in action!

Bray Plastics CNC machine a diverse range of plastic materials. Acrylics, acetal, PVC, ABS, Nylons, Polycarbonate and PTFE to name just a few. These materials are used throughout industry and in a large number of cases have replaced the more…

Ringing the alarm on illegal mobile phones

Illegal mobile phones in Her Majesties prisons represent a huge headache for the authorities. Thankfully there are means and ways of detecting these devices. Specialist companies have devised electronic monitoring equipment that can pinpoint the mobile phone usage and location.…

Enclosures for Farsite

Farsite Communications designed a new system for monitoring status and capacity of industrial waste bins. They needed to house and protect the sensitive electronics to IP66 as well as overcome a number of application problems associated with mounting and installation…

Mould Machining & Vacuum Forming in Action

Holkirk Communications design mobile satellite installations. A new system was being displayed at an exhibition but needed the finishing cladding to integrate the system to the vehicle and make it more aerodynamic. They needed help and turned to Bray Plastics…

Machining of Duratec 750® components

Duratec 750® is a calcium silicate based ceramic material and is one of a range of materials Bray machine for their customers. This particular component is machined from sheet stock and produced in batches of 500 off. It is representative of…

Plastics engineering expertise for specialist applications

With a history of machining and fabricating with acrylic materials, Bray’s engineering expertise is used by research institutes and scientific laboratories for specialist applications, such as:- X-ray Acrylic panels for isolation cabinets Custom PVC filter housings for chemical and biological…

Large vacuum forming of ABS

Large vacuum forming of ABS (acrylonitrile butadiene styrene), PE (polyethylene)and PP (polypropylene)is now within our capabilities. With a capacity from 100mm square right up to 2200mm x 1200mm we can help. Large area vacuum formings are a cost effective way…

Fabrication of PVC housing

This PVC housing is used inside isolation cabinets as used by biological and chemical research laboratories. It was designed as a replacement for a stainless steel version to reduce cost and weight. Bray applied its plastic fabrication skills to complete…

Design and Production of Plastic Containers

Peli Cases have a worldwide reputation for ruggedized cases and shipping containers. One of their UK subsidiaries have a multinational client who required modification to a standard case to enable the fitting of drawers. These would be used by their…

The Aviation Industry Calls on Bray Plastics

The general aviation industry has moved from paper to digital and solutions are required to enable pilots to be able to access the electronic devices used in the cockpit at all times. The devices need to be held steadily, easy…

AWE utilise Bray Plastics’ expertise with Premac®

Premac® is a lead loaded acrylic copolymer resin and is used for effective radiation shielding, including radiation from x-rays, whilst still being transparent for observations. Premac® is a very expensive material and has only one manufacturer in the world. The…

Bray Plastics move into the world of Virtual Reality

The world of virtual reality (VR) gaming is a multibillion dollar industry. The technical sophistication continues to ramp up to the point where the gamer can be completely immersed in the virtual world of the game. With the latest VR…

Acrylic machining

A component required for a medical application needed to be machined from a solid slab of Acrylic 50mm thick. Bray have a heavy duty router with a work area of 2 meters by 3 meters which was suitable for the…

Lasered foam profiles

How can you cut soft materials such as foams, felts, leather, Velcro and woven polymers etc., especially if they have adhesives that can clog up standard cutting tools. Bray Plastics have a state-of-the-art, in-house laser cutting facility and these soft…

Kneemount for Tablet PC

Here at Bray Plastics we are known for being able to provide design and fabrication solutions to a wide range of unusual projects. We pride ourselves on creating unique products that fulfill all criteria within budget and timeframe, no matter…

Foam and Polypropylene Fabrication of Dampener

Here at Bray we are regularly tasked with finding design and fabrication solutions so that products can suit a variety of applications. Our experience provides us with the expertise to match materials and fabrication techniques to the desired application. This…

Bray Help New Designers

Bray were pleased to help Nick Abrams produce his concept model for presentation at Coventry University Degree show. This model represents the culmination of new skills learned and is a stepping stone in Nick’s career as a car designer and…

Laser Cutting

To service our customers who may require a broader manufacturing choice, Bray have installed a twin head laser for the cutting and engraving of plastic sheet materials.

What We Do

We provide a wide range of services, covering every stage of the production process. We offer bespoke machining and specialist plastic fabrications. Using our knowledge and expertise, working with you every step of the way to find the best solutions.…