Our Services

Vacuum Forming & Moulding

Vacuum forming (also known as thermoforming) is the process of heating a plastic sheet until soft then raising the mould into the softened plastic sheet while applying vacuum for pull the sheet tightly round the mould. Once cooled, the mould is then released from the forming which can then be cut out of the excess sheet and finished as required.

Vacuum forming of plastics can be an extremely cost effective way of overcoming a number of problems that face designers, with tooling for short runs easily justified. We produce our own tooling , which means our turnaround times are short, and we can supply prototypes to production runs in a variety of thermoplastic materials.

We can advise on materials and how this process may benefit your requirement from concept through to production.

Our Capabilities

- We can accommodate vacuum forming sizes from 100x100mm to 2m x 1.2m

- Vacuum forming can be created from 1mm to 6mm thick sheet

- Post-forming, we can offer finishing services such as trimming to height, machining holes/cut-outs or even fabricating extra parts onto the forming

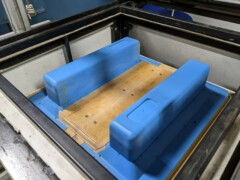

Example of a hard vacuum forming tool made from GRP with a high temperature gel coat. This is used for high volume production runs.

Finishing off a vac forming on the CNC router. Outside profile is trimmed to create an outside lip then cut-outs are made in the bottom.

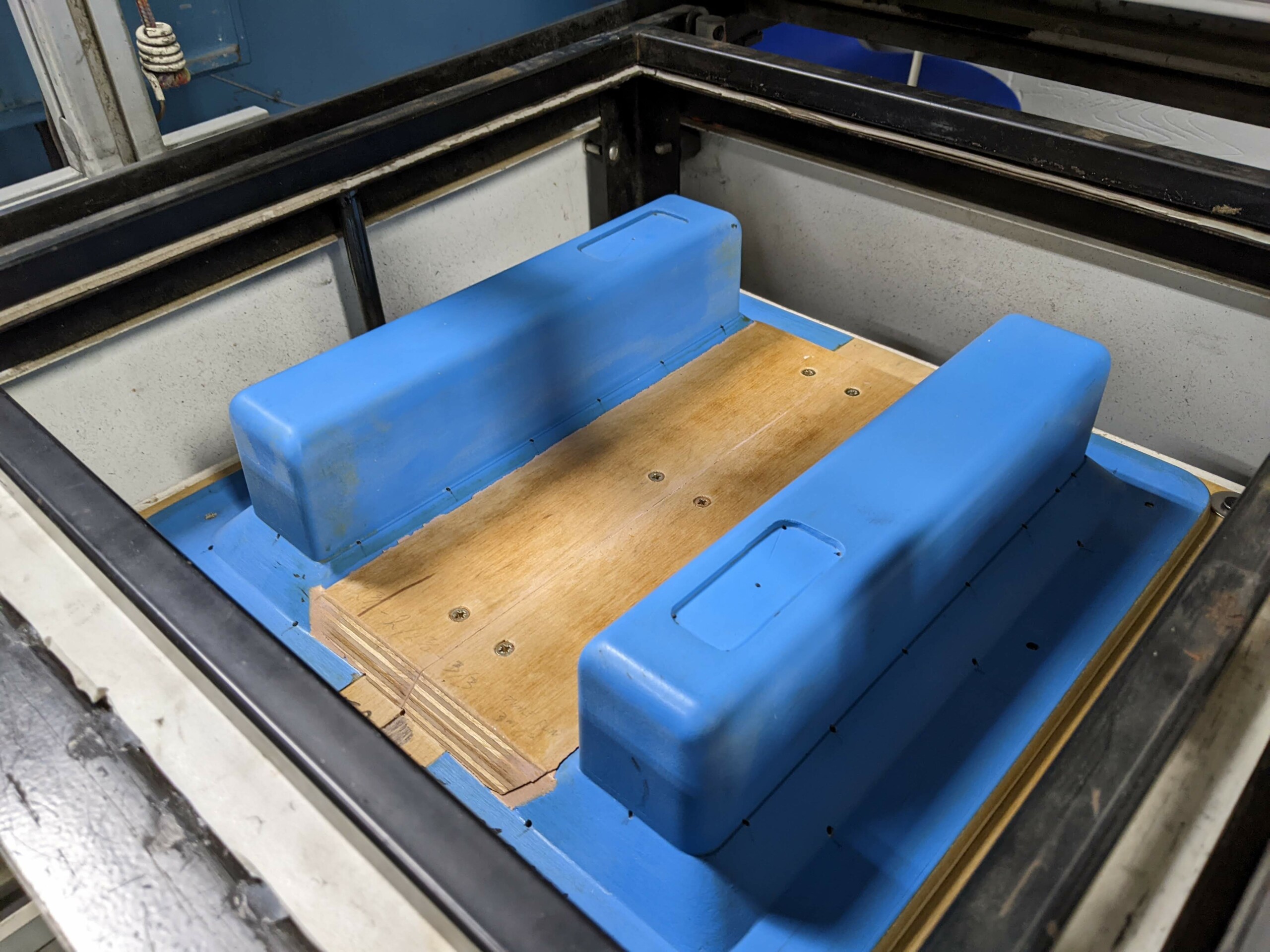

Multiple parts are often formed together from one blank sheet. Here, 3 parts are being formed together from 3mm black ABS. They will then be put on the CNC router to cut each one to the desired height.

Committed to High Quality Service

CNC Turning

CNC Turning

High precision guaranteed. Our expertise allows us to complete bespoke and challenging projects for demanding environments.

CNC Milling & Routing

CNC Milling & Routing

Precision engineered components in a wide range of plastics and metals with a fast turnaround.

Fabrication

Fabrication

Experts in a wide range of plastic fabrication methods, including machining, routing, welding, and in-depth knowledge of material specification, solvent and structural adhesives and mechanical joining techniques.

Vacuum Forming

Vacuum Forming

This lower cost forming technique can be applied to small and large components. It is used for a huge range of industry applications.

Prototyping & Tooling

Prototyping & Tooling

Our range of production equipment allied to our skill set enables us to offer prototyping services from single component through to assemblies.

3D Printing

3D Printing

We have two printers – a FormLab 2 SLA unit for fine detail and a 3DP FDM (Fused Deposition Modeling) unit with a massive build volume of 1 metre x 1 metre x 500 mm

Laser Cutting

Laser Cutting

We have a twin head 150 watt laser for laser cutting and engraving of corrosive plastic sheet materials, as well as a 1500×2500 flat bed 150 watt laser for fine quality high finish production.

Enclosures

Enclosures

We machine injection moulded and cast aluminium enclosures as well as designing and manufacturing custom enclosures and enclosure sourcing and modification.