Our Services

Plastic Fabrication

Although fabrication can be used to cover all aspects of plastic processing (including machining, turning etc), in this section we will be focusing on the other fabrication services we offer.

Plastics can be formed, welded and bent in much the same way as steels. These fabricating techniques allow designers to take advantage of plastic’s properties of corrosive resistance, finish, weight, Wi-Fi compatibility strength and clarity. We can also flame polish or buff suitable materials to enhance surface finish.

When it comes to joining plastic parts together, we can either use:-

- Chemical bond – This provides excellent mechanical strength by “melting” the surfaces being bonded to create one cohesive part. MEK or methylene chloride are some of the more common chemicals used for bonding in this process. Ideal for clear materials such as acrylic and polycarbonate as well as ABS and HIPS

- Structural bond – This process is often undertaken using a 2 part adhesive. Structural adhesive come in many different types for specific uses, enabling the bonding of many different plastics.

- Welding – Welding uses a filler rod, similar to metal welding. The heat then melts the filler rod into the 2 plastic surfaces to be joined. Ideal for PVC, polypropylene, and polyethylene.

- Mechanical fixings – These can be metal or plastic off-the-shelf fastenings. These can be simple nuts and bolts or screws into metal inserts which provide greater thread strength

Our understanding of the vast array of qualities available in modern plastics and the different processing techniques allows us to provide invaluable advice and find the most suitable and cost effective technique for your project. We actively source suitable environmentally-friendly options using recycled and recyclable plastics where possible.

Our Capabilities

- Plastic bonding (chemical, structural, welding and mechanical)

- Line bending

- Flame polishing & buff polishing

- Drape Forming

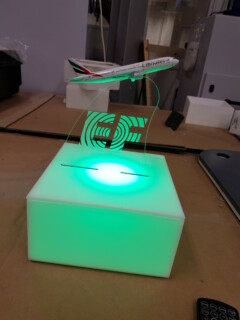

Line bent seat parts for use in airliners. Made from black Kydex.

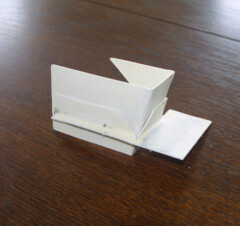

Custom cover made from black acrylic capped ABS. CNC machined, then line bent to form a box and chemically bonded together.

Medical filter housing fabricated from PVC tube and sheet. PVC welding is used to join the components together.

ABS drawer system fabricated to fit 1630 Peli Cases.

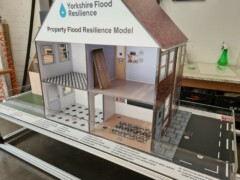

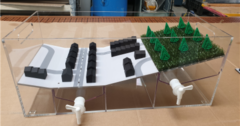

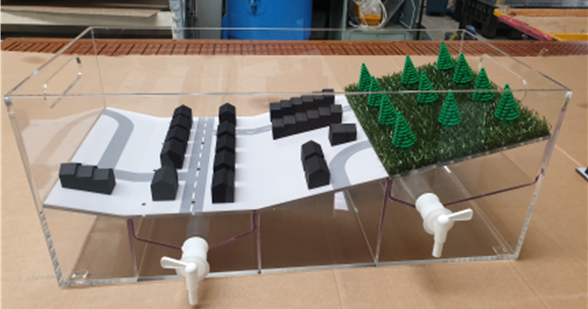

Surface drainage model demonstrating how different rural and urban areas effect water drainage. This is made from recycled clear acrylic, with a line bent centre place and everything chemically bonded together.

Committed to High Quality Service

CNC Turning

CNC Turning

High precision guaranteed. Our expertise allows us to complete bespoke and challenging projects for demanding environments.

CNC Milling & Routing

CNC Milling & Routing

Precision engineered components in a wide range of plastics and metals with a fast turnaround.

Fabrication

Fabrication

Experts in a wide range of plastic fabrication methods, including machining, routing, welding, and in-depth knowledge of material specification, solvent and structural adhesives and mechanical joining techniques.

Vacuum Forming

Vacuum Forming

This lower cost forming technique can be applied to small and large components. It is used for a huge range of industry applications.

Prototyping & Tooling

Prototyping & Tooling

Our range of production equipment allied to our skill set enables us to offer prototyping services from single component through to assemblies.

3D Printing

3D Printing

We have two printers – a FormLab 2 SLA unit for fine detail and a 3DP FDM (Fused Deposition Modeling) unit with a massive build volume of 1 metre x 1 metre x 500 mm

Laser Cutting

Laser Cutting

We have a twin head 150 watt laser for laser cutting and engraving of corrosive plastic sheet materials, as well as a 1500×2500 flat bed 150 watt laser for fine quality high finish production.

Enclosures

Enclosures

We machine injection moulded and cast aluminium enclosures as well as designing and manufacturing custom enclosures and enclosure sourcing and modification.