What is Laser Cutting?

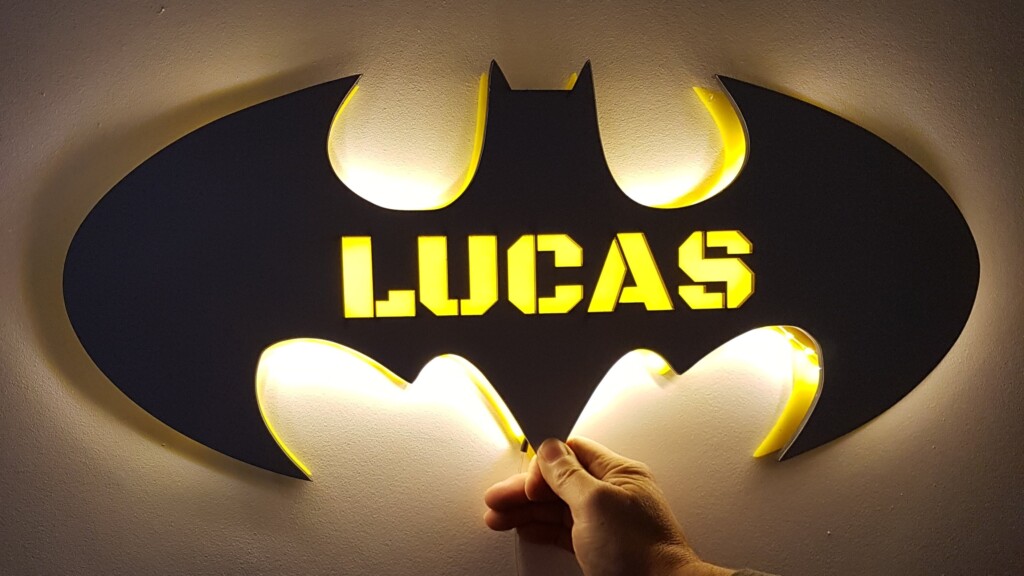

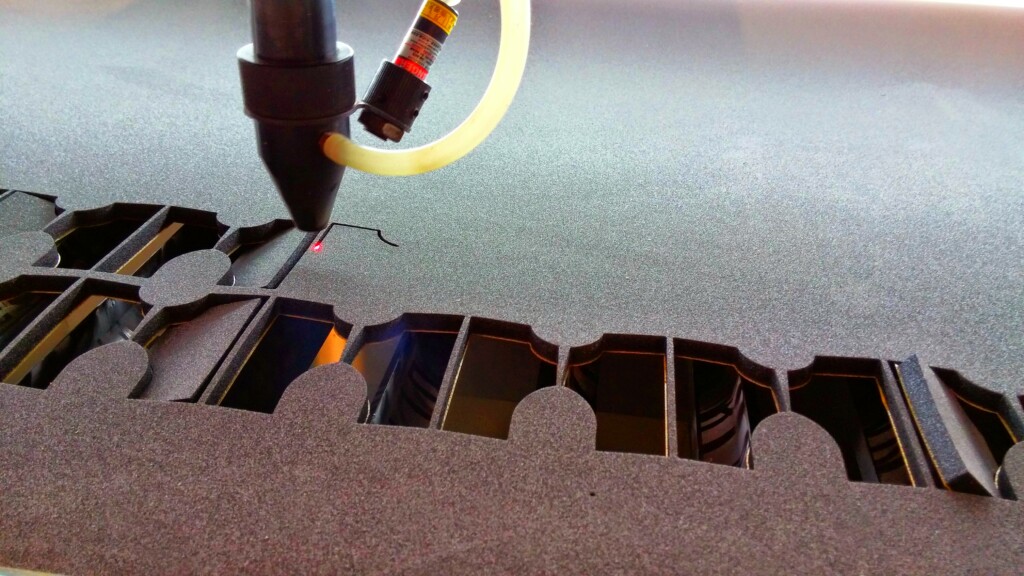

Laser cutting is a technology that uses a thin, focused laser beam to vaporise, burn or melt materials, resulting in a cut edge or etched surface, depending on your requirements. It is typically used for industrial manufacturing applications, but it is also becoming increasingly popular in small businesses, schools, and even homes.

The laser cutting head is typically mounted on a CNC machine, which allows it to move precisely over the material. The CNC machine follows a pre-programmed path, which guides the laser beam along the desired cut line.

Here at Bray Plastics we use CO2 lasers which work by sending an electrical current through a glass tube filled with CO2. Electricity flows through the gases, causing them to produce light. The light is them reflected by various precisely positioned mirrors before finally being focused through a lens to create a clean and precise cut.

Our lasers are ideal for cutting:-

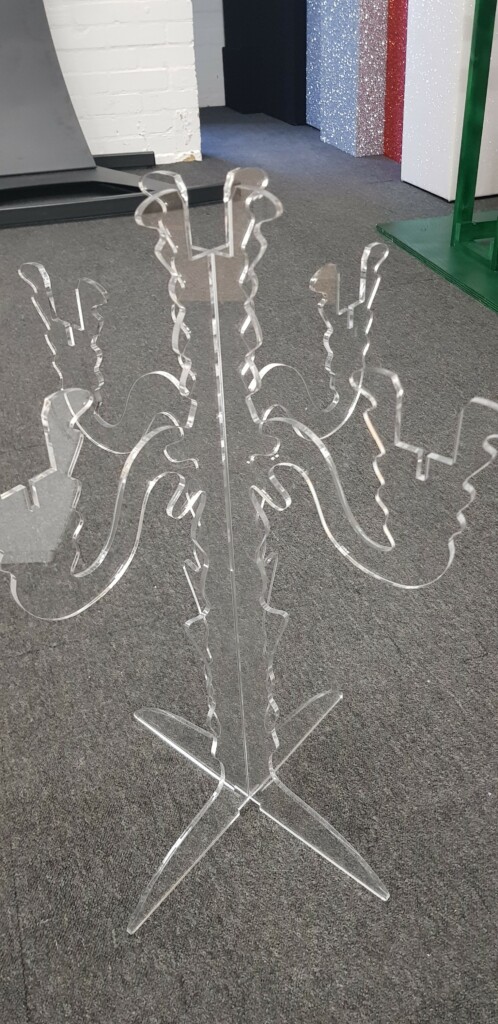

– Acrylic (up to 12mm thick)

– PTFE (up to 3mm)

– ABS (up to 3mm)

– PE (up to 2mm)

– Kydex

– HIPS

– Neoprene rubber (up to 4mm)

– Polycarb (up to 4mm)

– Plywood (9mm)

– MDF (12mm)

– Fabric

– Velcro

– Strapping

– Foam

Advantages of Laser Cutting

Laser cutting offers a number of advantages over other cutting methods, such as water jet cutting, plasma cutting, and mechanical cutting such as routing and milling. These advantages include:

- Precision: Laser cutting can produce extremely precise cuts and details with a very fine laser beam of only 0.3mm. This makes it ideal for cutting complex shapes and features.

- Speed: Lasering is a very fast process, with speeds of 400mm/second for engraving and 50mm/second for cutting This makes it ideal for high-volume production applications.

- Versatility: Laser cutting can be used to cut materials, that would be more difficult to cut using conventional milling and routing techniques, such as fabrics, cardboard, foam and rubber.

- Minimal heat-affected zone (HAZ): The laser beam produces a very small HAZ, which minimizes the amount of distortion and warping of the material being cut.

- Smooth edges: Laser cutting produces smooth edges, which often do not require further finishing.

Disadvantages of Laser Cutting

Disadvantages include:-

- Limitations on the materials which can be cut

- Limitation on the thickness of materials which can be cut

- Laser cutting some materials, especially plastics, produces harmful fumes and gases which need to be extracted properly.

- Dimensional tolerance isn’t quite as good as with CNC routing/milling

Conclusion:

Bray Plastics offers laser cutting as a time and cost-effective profiling and engraving process. Contact us today to find out how we can help you with your next project!