Prototyping and conceptual design seems to be dominated by the 3D print market at the moment. Clever software allied to the plethora of 3D printers has inspired the industrial press that innovation comes down to kit.

Granted, in some cases this will have an element of merit but real innovation is still initiated in the head of the designer and his team with a large dose of good old fashioned ‘elbow grease’.

Components do not always have to be hugely complicated to warrant prototyping for approval. Size, material and fitness for purpose may restrict the new technologies. However, the requirement still has to be fulfilled.

Creating prototype components for Peli BioThermal

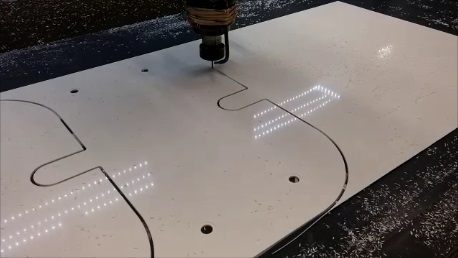

Peli BioThermal is a world leader in thermal packaging, they use innovative design to enhance their products for their customers, prototyping large components in polypropylene and polystyrene foams. These can be used and tested to obtain ‘real world’ data before committing to tooling and production methods.

Bray Plastics have been pleased to help Peli BioThermal by machining these foams. Intricate shapes and forms have been achieved on time and budget enabling both proof of concept, fit and application. Do you have a project where we could provide our cost effective prototyping services. Get in touch!

If Bray Plastics can help with your enclosure requirements, please call.