What is Vacuum Forming?

Vacuum forming is a manufacturing process that uses heat and vacuum to shape plastic sheets into three-dimensional objects. It is a relatively inexpensive process that can be used to produce high-quality parts in a short amount of time. It is also a relatively safe process, as it does not involve the use of harmful chemicals or solvents.

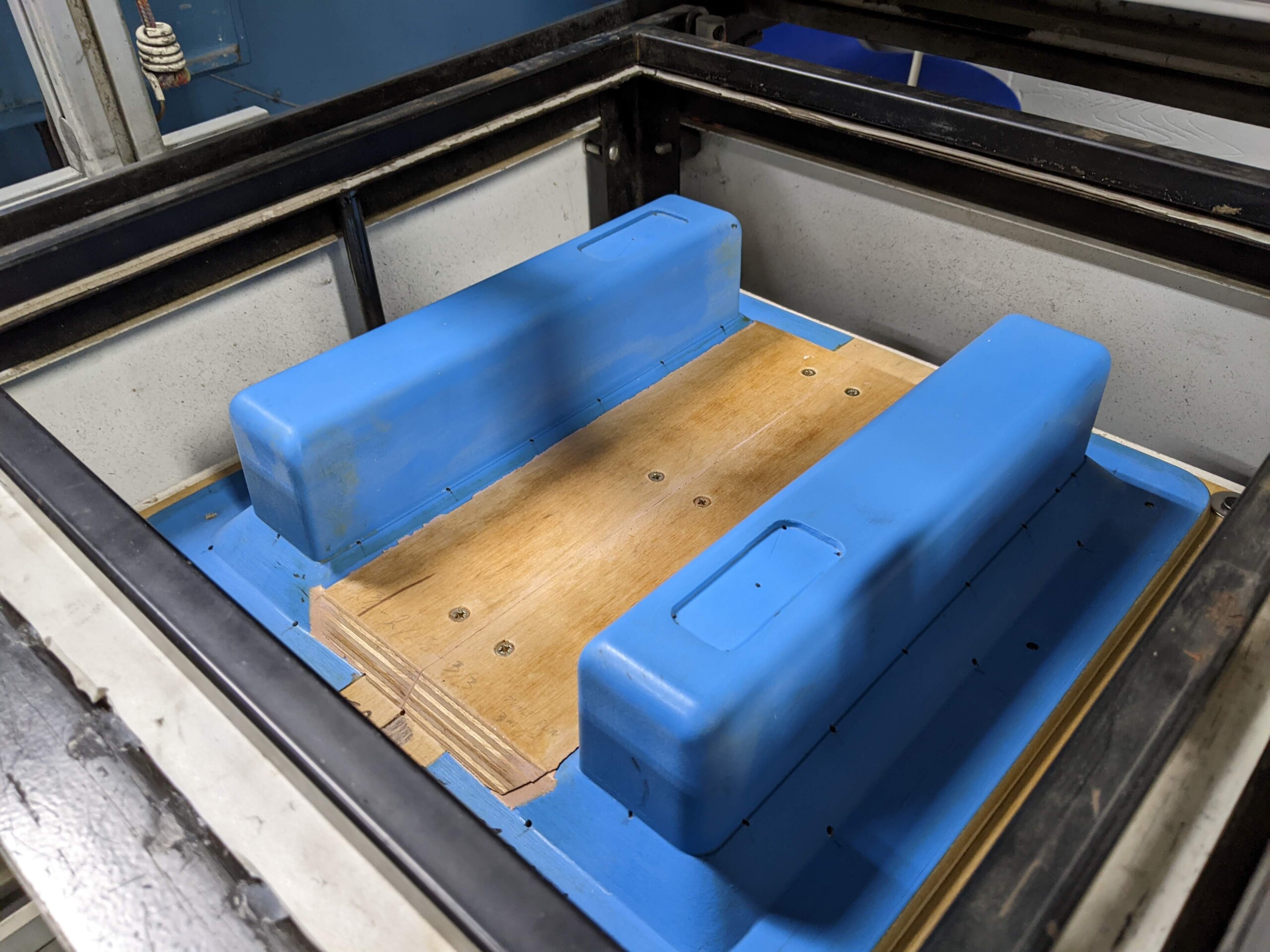

In order to produce a vacuum forming, the first thing needed is a mould. These are typically made from MDF, resin or modelling board for low volume runs or epoxy, fibreglass and aluminium for high volume runs. The mould needs to be designed with tapered sides (minimum of 2 degrees) to facilitate the release of the finished plastic part from the mould. Here at Bray Plastics, you can supply us with a mould you already have or we can manufacture a mould from scratch for you.

Depending on the type of plastic being formed, the sheets may need to be dried in the oven before they can be vacuum formed. Materials such as ABS & polycarbonate naturally absorb moisture from the air over time. Normally this doesn’t cause an issue but when the plastic is heated up quickly and to the high temperatures needed in the forming process, the heat causes the water molecules to boil which produces bubbles in the finished forming. Heating the sheets in the oven even if they don’t specifically need drying is also helpful in reducing the vacuum forming time for each part as they will need less heating on the vacuum former.

While the plastic is drying/heating in the oven, the vacuum former can be set up. The mould is attached to an MDF base which can then be bolted to the vacuum former table. A forming “window” of the correct size if then selected and bolted to the vacuum former. The “windows” are a selection of steel sheets, each with a different size cutout, selected to fit around the mould with ideally a gap all round approximately equal to 1.5 times the height of the mould. The plastic sheet size needed for the forming is governed by this cutout as it needs to be approximately 1.5” wider than the cutout all round.

When ready to form, the plastic sheet is placed over the cutout in the “window” then a frame clamp on the vacuum former is brought down over the sheet and clamped into place. The table with the mould on sits out of the way, underneath the plastic sheet at this time. The vacuum former heater is then brought forward over the sheet. The sheet is ready to form once it becomes flexible and droops in the middle.

The table with the mould on is moved upwards, into the flexible plastic. At the same time, vacuum is applied, drawing the plastic around the tool. This process needs to be done quickly to ensure the plastic stays hot and flexible. The plastic is then cooled and removed from the mould.

Vacuum forming is ideally suited for products such as:

● Displays

● Signs

● Trays

● Covers

● Toys

● Appliance parts

● Automotive parts

● Medical devices

Benefits of vacuum forming:

● Versatility: Vacuum forming can be used to create a wide variety of products.

● Speed: Vacuum forming can be used to produce high-quality parts in a short amount of time.

● Cost-effectiveness: Vacuum forming is a relatively inexpensive process, tooling is much cheaper than injection moulding tools.

● Safety: Vacuum forming is a relatively safe process.

Drawbacks of vacuum forming:

● Limited detail: Vacuum forming is not as precise as some other manufacturing processes, such as injection moulding.

● Thickness: Vacuum formed parts are typically limited in thickness.

● Waste: Vacuum forming can produce a significant amount of waste material although this can often be recycled.

Conclusion:

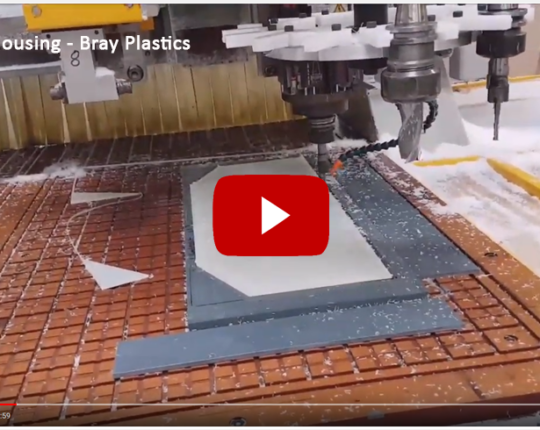

Bray Plastics offers vacuum forming as a versatile and cost-effective manufacturing process that can be used to create a wide variety of products. The finished forming can be modified further using our CNC routing/mill and fabrication expertise. Contact us today to find out how we can help you with your next project!