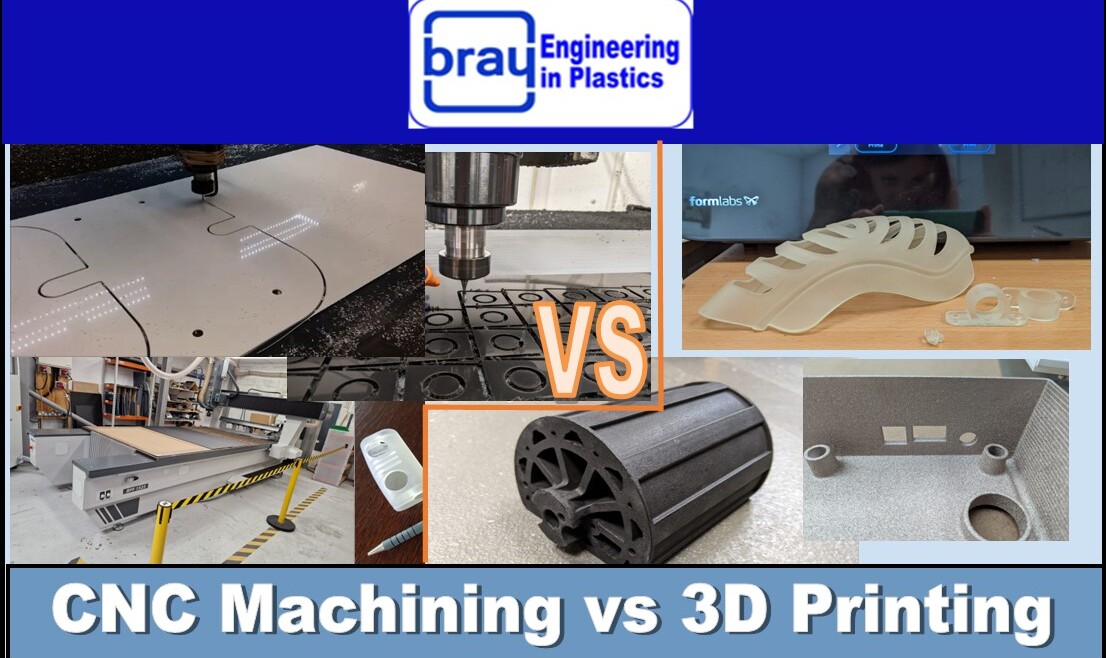

CNC Machining vs 3D Printing – Which Process is Right for Your Project?

So, you’ve got the design sorted and are now ready to take your project to the next stage. But what’s the difference between CNC machining and 3D printing and which one is right for your project? Lets have a look….

At a Glance: CNC vs 3D Printing

| Feature | CNC Machining | 3D Printing (Additive) |

| Process | Subtractive – removes material from a solid block | Additive – builds up material layer by layer |

| Materials | Plastics (PEEK, PTFE, Acrylic), metals (Al, Ti, Steel) | Mostly plastics (ABS, PLA, Nylon), resins, composites and some metals |

| Strength | Isotropic – full material strength in all directions | Anisotropic – weaker between layers |

| Precision | ±0.05mm – ±0.2mm | ±0.05mm – ±0.2mm |

| Surface Finish | Excellent (as-machined or polished) | Often requires post-processing |

| Best For | Production parts, tight tolerances | Prototypes, complex internal geometries |

When to Choose CNC Machining

✅ You need volume production-grade parts

✅ Working with engineering plastics or metals (e.g., PEEK, Aluminium)

✅ Need full mechanical strength (no layer lines)

✅ Want superior surface finish straight from the machine

When to Choose 3D Printing

✅ Rapid prototyping (same-day models)

✅ Complex internal geometries (hollows, lattices, undercuts)

✅ Low-volume customisation without tooling

✅ Testing form and fit before committing to CNC

Cost & Lead Time Comparison

| Volume | CNC | 3D Printing |

| 1–5 parts | Higher setup cost | Cheaper & faster |

| 10–100 parts | Cost-effective | Still viable |

| 100+ parts | Most economical | Expensive per part |

Pro Tip: Use 3D printing for prototypes, then switch to CNC for production.

Hybrid Approach (Best of Both)

- 3D Print → Validate design quickly

- CNC Machining → Produce final parts in target material

Bray Plastics offers both – seamless transition from prototype to production. We also offer injection moulding, another great option to further your project after prototyping and low volume runs!

Whether its prototyping or low/medium volume production runs with final assembly (and everything in-between!), we love a challenge, so contact us today!

Thanks!

The Employee Ownership Team at Bray Plastics