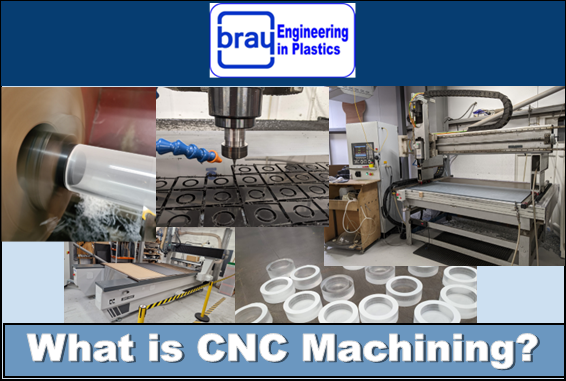

At Bray Plastics Ltd, we specialise in CNC machining – the gold standard for creating high-precision plastic and metal components. Whether you’re in medical devices, aerospace, electronics, or automotive, CNC delivers unmatched accuracy and repeatability.

But what exactly is CNC machining? Let’s break it down.

What Does CNC Stand For?

CNC = Computer Numerical Control

It’s a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. Think of it as a robotic sculptor, guided by digital designs to cut, drill, mill, or turn raw materials into finished parts with micron-level precision.

How CNC Machining Works (Step-by-Step)

- Design – Your part is designed in CAD CAM (Computer-Aided Design & Computer-Aided Manufacturing) software.

- Programming – The design is converted into G-code (the language CNC machines understand).

- Setup – Material is secured in or on the CNC machine (mill, lathe, router, etc.).

- Machining – The machine automatically removes material to form your part.

- Finishing – Polishing, anodising, or assembly as required.

Why Choose CNC Machining?

| Benefit | What it Means for You |

| Precision | Tolerances as tight as ±0.05mm (depending on material) |

| Versatility | Works with plastics (Acrylic, PVC, PTFE, Acetal to name just a few), metals, composites |

| Speed | Rapid prototyping |

| Repeatability | Identical parts every time |

Common Materials We Machine at Bray Plastics

- Engineering Plastics: ABS, PVC, PTFE, Nylon, Acetal, PE, HIPS

- Clear Plastics: Acrylic, Polycarbonate (optical-grade)

- Metals: Aluminium, Stainless Steel

Vacuum forming, fabrication, and laser cutting also available.

Real-World Applications

- Medical: Surgical instruments, device housings

- Electronics: Enclosures, connectors, heat sinks

- Automotive: Custom fixtures, prototypes, light lenses

- Aerospace: Lightweight brackets, ducting components

Whether its prototyping or low/medium volume production runs with final assembly (and everything in-between!), we love a challenge, so contact us today!

Thanks!

The Employee Ownership Team at Bray Plastics