Client: ProEconomy

Project: Updating and re-engineering of water treatment station

Overview:

ProEconomy approached Bray Plastics looking to enhance their proven and successful ‘Orca’ water treatment station for Legionella control. Orca required updating for engineering, servicing and customer interface.

After we reviewed the requirement, Bray re-engineered the layout and mounting base, added graphics and generally repackaged an already very effective product.

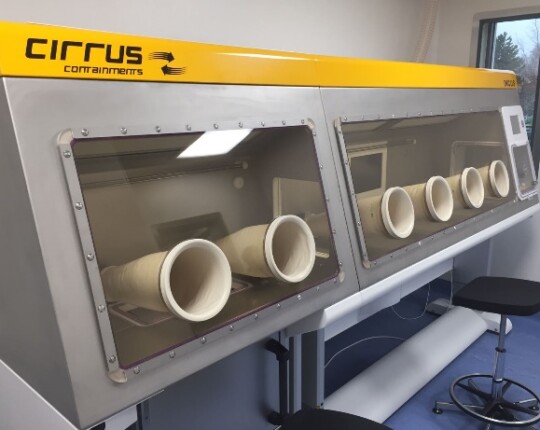

Before and after the redesign

Solutions:

Using our skills in design, plastic machining, fabrication, vacuum forming and assembly we worked closely with ProEconomy staff to quickly achieve a highly commercial product.

Testimonial:

When my company, ProEconomy needed to upgrade the manufacture, performance and aesthetics of its water treatment equipment for Legionella control, finding the right supplier at first seemed daunting. However having received an introductory mailer from Bray Plastics, I decided to contact them to outline our requirement. From the outset, the guidance and expertise I received was reassuring and courteous. I was impressed with their willingness to take responsibility on my behalf to see the project through to its conclusion. The design improvement to our product is marked, the quality, finish and appeal have raised the profile of our equipment to higher level. Bray Plastics expertise has significantly helped ProEconomy achieve a world class product on time and on budget.

Byron Bedford, MD. ProEconomy.